Technology Protection

The concept has two aims

The concept of «technology protection» for gloves and hoods has two aims:

- to maintain our position as a forerunner and in the Marmon Group as concerns all its glove and hood design/manufacturing activities

- expand its expertise in the development of new gloves and hoods, with their interaction with users.

Our vast creative potential is entirely put to use for Procoves customers to support their own CSR and Zero Accident goals.

Our production and laboratory technologies are the result of unique Procoves innovation capabilities combining 50 years of experience in innovative glove and hood design and manufacturing.

Our innovative glove and hood ecosystem allows us to create a unique network of long-term partnerships with the most advanced suppliers in the industry. Procovès is proud of its innovation expertise which has been recognized by leaders through all types of cooperation agreements and technology and brand licensing agreements with various companies :

Industry Segment

Glove and hood technology

Procovès has developed in own for different industries

Revolutionary technologies

Over the years, Procovès has developed its own technologies which have all revolutionized the use of gloves and hoods in the different industries we serve.

The ProcoTek glove technology offers the market a high level of demanding multi-risk protection and a comfort level never before seen with these protection levels.

The Procotek glove technology is the result of having developed our innovation service over several years in collaboration with our partners.

We’ve used our textile know-how (upwinding, knitting and coating) and creativity to assemble the most innovative materials in the most ideal manner to achieve an unbeatable protection and comfort ratio for gloves.

We comply with the protection requirements of the new standard EN388: 2016, up to the highest cut protection level (F) and meeting the requirements of thermal and electrostatic discharge risks for gloves.

Our Procotek glove technology is oriented

toward different types of environments:

Adapted to oily and wet environments

ProcoTek#n glove technology offers :

- comfort and durability due to the quality and breathability of our coatings

- excellent dexterity and a premium glove grip

- DMF-free guaranteed with a production process that takes place in an aqueous environment

- silicone-free guaranteed with an advanced glove production process

For dry environments

ProcoTek#p glove technology offers:

- immense comfort due to the quality and breathability of our coatings

- excellent dexterity and a premium glove grip

- skin protection guaranteed with <10 mg DMF

- silicone-free guaranteed with an advanced glove production process

Agrifood Segment

Glove technology

Whizard Technology

The original: often replicated but never equal

With its Whizard glove technology, Procovès has been pioneer in glove solutions which are resistant to cutting and suitable for the food industry.

Procovès has been able to meet the triple challenge posed by the food industry for several years now: maintaining very high protection levels, the original comfort even after several wash cycles at high temperatures and a competitive glove acquisition cost.

The Whizard glove technology is based on an original patented upwinding technology and the use of the best materials with a ten-year partnership with the Honeywell group relating to Spectra® fibre.

- extreme protection against cutting risks

- a food contact product that is certified in Europe and the USA against food contamination risks

- guaranteed skin protection with the Oekotex glove label

- excellent dexterity due to glove lightness and dimensional glove stability even after 50 washes at high temperature.

- an excellent overall glove acquisition cost as the most competitive on the market.

Firefighting Segment

Glove technology

The protection of firefighters textile gloves

With ANTARES glove technology

« Safety for mortal risks »

With its Antares glove technology, Procovès has been pioneer in lamination technology for protective firefighting gloves

The Antares lamination technology meets the extremely demanding requirements of comfort, durability and technical performance in the fire-fighting market. This textile technology makes it possible to assemble materials in the best way and combine the different properties of each glove material.

Antares glove technology offers :

- protection against the mortal risks fire fighters are exposed to

- excellent dexterity due to glove lightness and dimensional glove stability even after 5 washes

- savings with an overall glove acquisition cost as the most competitive on the market

Firefighting Segment

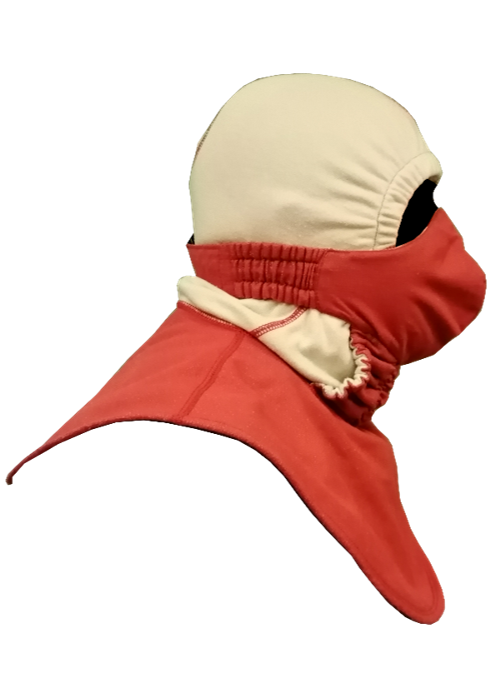

Hood technology

The protection of firefighters hoods

With Nomex® Nano Flex

Barrier protection technology

« Safety for mortal risks »

With Nomex® Nano Flex hood technology, Procovès has been pioneer in lamination technology for protective firefighting hoods.

The Nomex® Nano Flex lamination technology meets the extremely demanding requirements of comfort, durability and technical performance in the fire-fighting market. This textile technology makes it possible to assemble materials in the best way and combine the different properties of each hood material.

Nomex® Nano Flex hood technology offers :

- Thermal and barrier protection against the mortal risks fire fighters are exposed to

- excellent breathability due to hood lightness and optimal management of sweating

- an acoustic comfort thanks to the microtextile structure fitted to the environment

- savings with an overall hood acquisition cost as the most competitive on the market thanks to dimensional hood stability even after 50

washes.